As one of the most important and sensitive organs of the human body, the eyes are especially vulnerable in jobs such as welding. While eye-related injuries are among the most common accidents at work, experts say they are also the easiest to prevent. That’s why we suggest to use the right types of welding helmets.

Most welders are already well aware of the hazards they face on the job. Heat, sparks, flying debris, toxic fumes, and moving metal can all cause injury. When choosing a welding helmet, knowledge of the risks and the use of appropriate personal protective equipment can go a long way toward saving time.

How Do Welding Helmets Work

Arc welding produces three types of light: ultraviolet, infrared, and visible, which can damage the eyes of welders. In addition, welders are at risk of burns from sparks and hot molten metal. Welding helmets are designed to protect the welder's face and eyes from these hazards.The most basic helmet consists of a non-flammable face shield that is secured to the welder's head with an adjustable strap. The welder's eyes are cut out in a rectangle on the shield. In this rectangle, there is a welding lens covered by a protective screen. The welding lens is coated with a darker color to protect the welder's eyes from the various harmful rays emitted by the electric arc.

How To Identify Welding Lens Shades

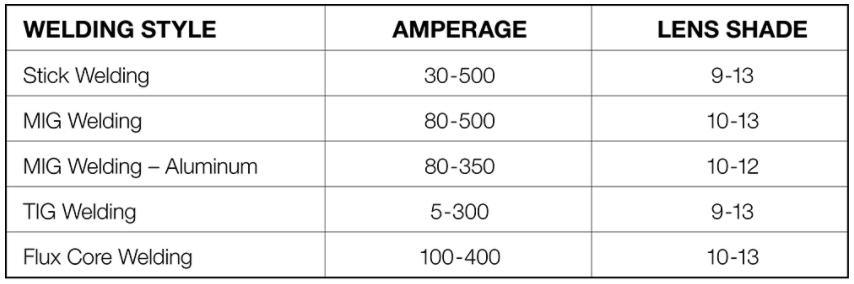

The higher the shade rating, the darker it is and the more light it filters. When choosing a welding helmet, the first thing to check is whether it has been tested and approved by the American National Standards Institute (ANSI). This will ensure that the helmet will keep you safe.

All welding helmets are equipped with welding lens shades designed to provide the right amount of eye protection for the job at hand. The best welding helmet for each job will depend on the specific visor and light control provided.

How Welding Helmets Should Fit

The best welding helmets on the planet won't do the job effectively if they don't fit properly. Here are some tips to help you get the right fit when choosing a welding helmet for your need:

-When you try on any helmet, wear a welding bandana. Welding bandanas are made of flame retardant material to protect your head and ears. When you put on your helmet, wear yours to ensure a snug, but not too tight, fit.

-Make sure your welding helmet can be properly secured to your head. The helmet should be tightened securely on your head, but do not put too much pressure on the bottom or top of your head.

-Check to make sure there is no unwanted movement when tightening your helmet comfortably. The best welding helmet should only move with your head, so tilt your head back and forward to check for a stable fit.

-Make sure you have enough space between your face and the front of your helmet. Being too close to the welding lens can make you feel uncomfortable and cause sweating and moisture related problems.

-Choose the lightest helmet possible. A lightweight helmet that meets all the requirements for use is the most comfortable and puts the least strain on the neck. This is especially important if you will be welding for long periods of time.

After knowing how to choose the best welding helmet for you, SINOTOOLS welcomes any inquiry as a professional and trusted PPE supplier. If you are in need of welding helmets or masks, contact us now and get a discounted price.

Copyright © Hebei Sinotools Industrial Co.,Ltd. All Rights Reserved | Powered by  Sitemap

Sitemap